A research team at the University of Virginia School of Engineering and Applied Science (Charlottesville, Va.; engineering.virginia.edu) is the first to explore how an emerging plant-based material, cellulose nanofibrils, could amplify the benefits of 3D-printed concrete technology.

“The improvements we saw on both printability and mechanical measures suggest that incorporating cellulose nanofibrils in commercial printable materials could lead to more resilient and eco-friendly construction practices sooner rather than later,” said Osman E. Ozbulut, a professor in the Department of Civil and Environmental Engineering.

His team’s findings will be published in the September 2024 issue of Cement and Concrete Composites.

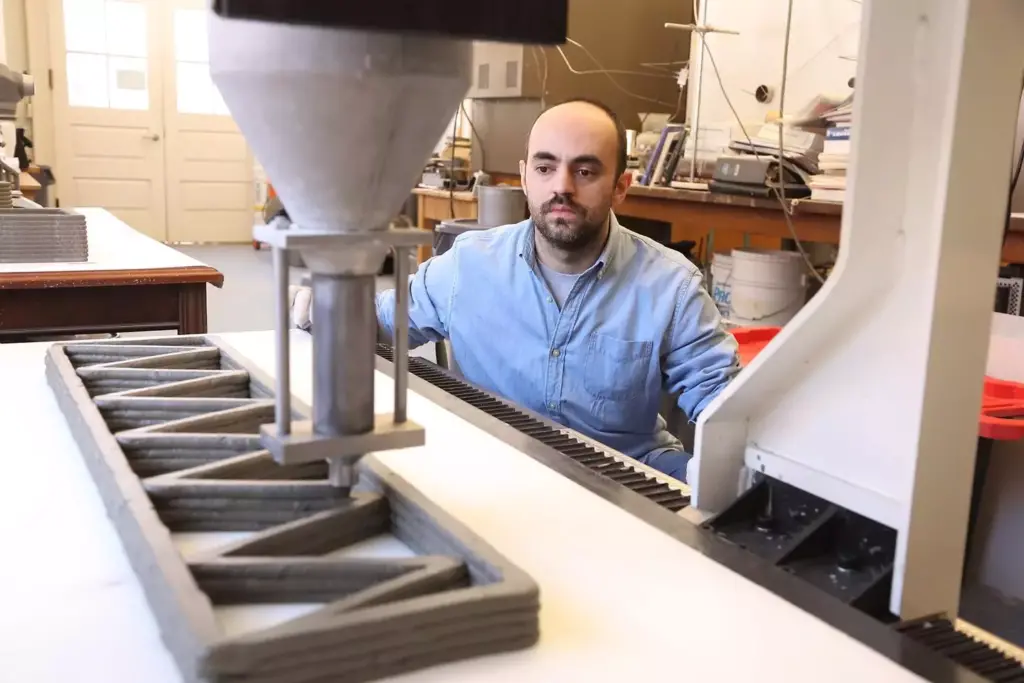

Ugur Kilic, a University of Virginia civil engineering Ph.D. student, keeps an eye on the concrete printer in Professor Osman Ozbulut’s lab at UVA in this 2022 photo. (Tom Cogill, UVA Engineering)

Buildings made of 3D-printed concrete are an exciting trend in housing, and they offer a slew of benefits: Quick, precise construction, possibly from recycled materials, reduced labor costs and less waste, all while enabling intricate designs that traditional builders would struggle to deliver.

The process uses a specialized printer that dispenses a cement-like mixture in layers to build the structure using computer-aided design software. But so far, printable material options are limited and questions about their sustainability and durability remain.

“We’re dealing with contradictory objectives,” Ozbulut said. “The mixture has to flow well for smooth fabrication, but harden into a stable material with critical properties, such as good mechanical strength, interlayer bonding and low thermal conductivity.”

Cellulose nanofibrils are made from wood pulp, creating a material that’s renewable and low impact. Like other plant-fiber derivatives, CNF, as the material is known in industry, shows strong potential as an additive to improve the rheology — the scientific term for flow properties — and mechanical strength of these composites.

However, until the UVA team’s meticulous study in Ozbulut’s Resilient and Advanced Infrastructure Lab, the influence of CNF on conventional 3D-printed composites wasn’t clear, Ozbulut said.

“Today, a lot of trial and error goes into designing mixtures,” he said. “We’re addressing the need for more good science to better understand the effects of different additives to improve the performance of 3D-printed structures.”

Experimenting with varying amounts of CNF additive, the team, led by Ozbulut and Ugur Kilic, now a Ph.D. alumnus of UVA, found that adding at least 0.3% CNF significantly improved flow performance. Microscopic analysis of the hardened samples revealed better material bonding and structural integrity.

In further testing in Ozbulut’s lab, CNF-enhanced 3D-printed components also stood up to pulling, bending and compression.